I have been wanting to write about this problem for sometime and I was just looking for a good opportunity. At least, I did not have to wait too long! I received a broken EB832 from a fellow reefer for repair and before opening the unit, I already knew exactly what the problem was going to be.

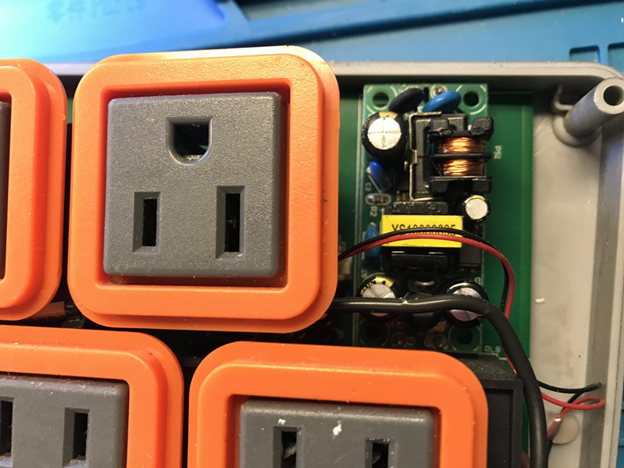

But just knowing is not going to do this poor EB832 any good! We need to get it working again. I open it up and notice that this particular EB832 is very, very clean. There is no salt, oxidation or anything inside or outside that would suggest that the failure is due to negligence. So what is wrong then?

Oh look! There it is like that shy girl at a prom dance sitting in the corner and wondering if anyone will notice her.

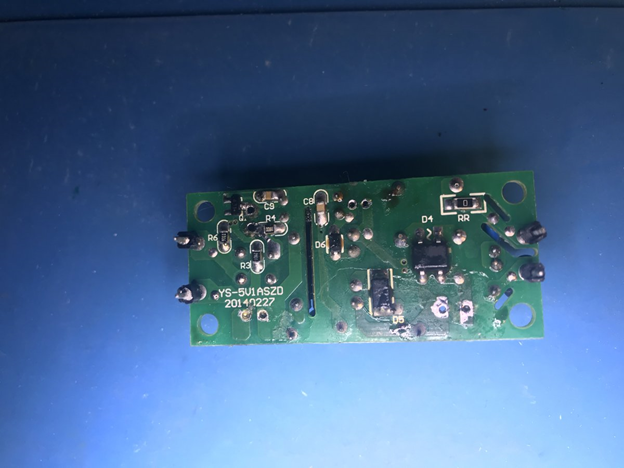

Yes, this is our little 12V AC to DC power supply model YS-5V1ASZD. Its only purpose in life is to provide power to a couple of controllers so that the EB832 can communicate with Apex head unit over aquabus. Well that and so that it can also switch outlets on and off. Both tasks are kind of critical to the proper operation of the entire unit, like oxygen to a brain.

So just like that shy prom girl, our little PSU has a big heart filled with the motivation to do the best that it can to make this humongous unit a better place by providing power to critical components. But it does not know yet that it really cannot do that or that it really should not be forced into this situation. Why? Let us take a closer look at the PSU.

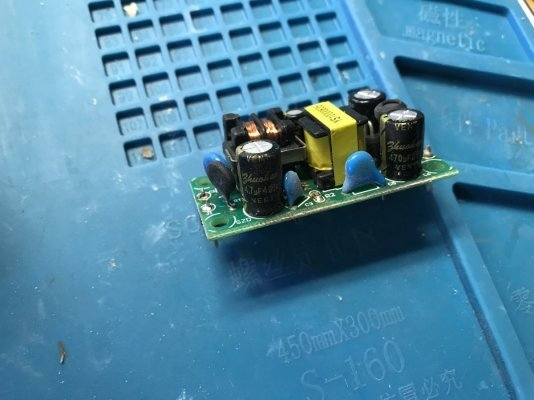

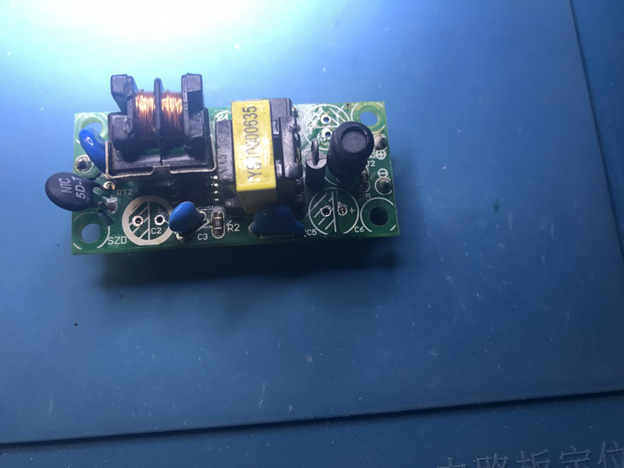

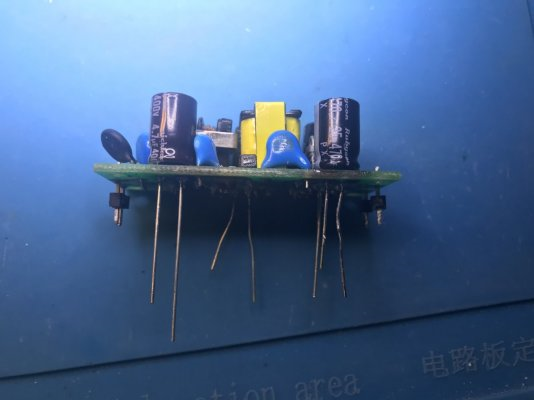

From the markings, we would assume that it is a 5V 1A power supply, but it is not. It is a 12V PSU, probably 1A or less and that should be plenty big to empower those ICs. The design is very common. I believe that this particular one is open sourced and widely available. On the board, we see all kinds of prefilters, coils, and capacitors. So why can it not do what it was designed for? Let us take a slightly different angle.

First, can you see a somewhat bulged capacitor on the left? This is where it all starts. Now you get to read my rant.

<RANT>

Capacitors fail often. They are both very critical and yet represent the most common failure in power supplies, but not all capacitors are the same. Every device with electronics needs a PSU, yet not every device fails due to a PSU in the first 2 years of operation. This suggests that some PSUs that do not fail as often use capacitors that are somehow different. I would even go on a limb and say that they might be…oh, I do not know…of a higher quality. This way, they last longer and work better. Let’s take a look at what Neptune chose for their EB832.

Zhuohao capacitors? Zhuohao are not just low quality, but they are the bottom of the bottom of the barrel capacitors. You can pretty much only source them directly from China. No reputable electronics supplier in the US carries them. Just google them to get some juicy details from the electronics community.

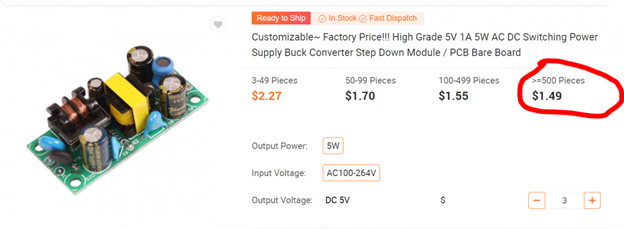

As it was previously mentioned, this entire PSU assembly (including capacitors and whatnot) can be purchased retail at ~$3-4 shipped.

These particular PSU are really hobby grade items. If you are into Arduino tinkering, then it is a good option to prototype a toy project.

What I am struggling to understand is why Neptune decided to use it in their equipment. Yet, they position the entire Apex line as a high end, reliable reef controller.

It is so unique that they force retailers into MAP policy. And speaking of price, I do not think many people consider it particularly cheap. The high price tag comes with the expectation that the quality matches the price. But more importantly, the reefing community trusts these controllers to run their tanks 24/7 for years. They trust EB832 to turn on critical tank equipment. By association, EB832 itself is in fact becomes a critical piece of equipment.

So why are we finding a hobby grade $3 (retail) third party module inside a $280 power bar? The module that, if failed, disables the entire unit and anything plugged into it?

Neptune did not even implement this module. They bought a truck load of them on alibaba because they are probably $1 or less each wholesale.

<END OF RANT>

Enough ranting! This poor EB832 is still hurting and needs to be fixed.

Of course, there is always an option to just replace the failed PSU with a working one. But the problem is that we would be replacing one subpar component with another component, which is equally subpar. What if we fixed the component by replacing very low quality parts with something that is going to actually last past Neptune’s meager 1 year warranty?

After all, the design of the PSU is very common and actually good enough for what it must do. It is the choice of parts to implement it that is questionable.

To verify the theory that this PSU is our problem, we will perform a quick diagnostic. The PSU is rated up to 1A current. It also has a red LED on the DC side to indicate that it is working properly and just because this LED is on, does not mean that the unit is working to the specs. We will apply a reasonable load with a small computer fan with 0.25A draw to the DC side to see if the PSU can power it up. In my experiment, the fan did not spin and the red LED immediately turned off under the load. The capacitors are bad.

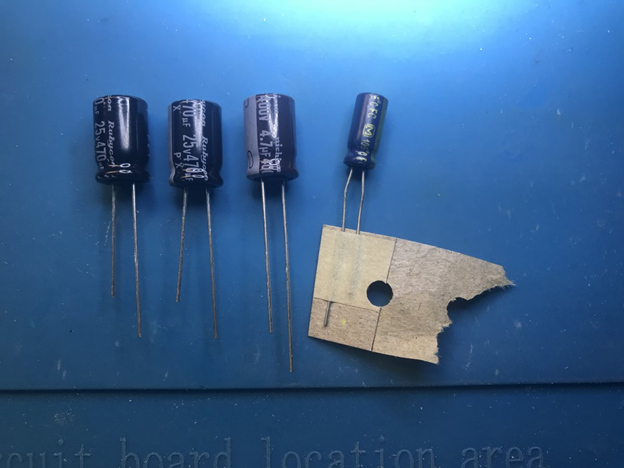

To fix this, we will remove all capacitors on board, regardless of their condition. We do not want that junk as we can never be sure how much longer they will last. All caps removed and the area is clean and ready for the good stuff.

And speaking of the good stuff for the fix, we have a healthy mix of brand new Panasonic, Rubycon and Nichicon capacitors. All top brands with longest life available.

These capacitors together probably cost more than the entire PSU unit they are going into.

They fit nice and clean into the original spots on the board.

Let us clip excess leads and the module is all back together and ready to go.

I tested it with the same 0.25A fan and now the fan spins and the red LED stays on. The PSU is now fixed.

Once it is back inside the EB832, the red LED stays on and the EB832 is happy again.

We can make your Apex work again. Head over to the Mail-In Repair section to find out how to send us your device for repair.